ALUMINUM ALLOYS

Homogeneous Mixture-Type Aluminum Brazing Filler Metals

What is a homogeneous mixture-type aluminum brazing filler metal? An aluminum brazing filler metal in which the filler metal and flux are uniformly mixed throughout, ensuring a consistent composition and performance.

Discover the Advantages of Homogeneous Mixture-Type Aluminum Brazing Filler Metals

Consistent flux content

Consistent and exceptional brazing quality

Safer and cleaner working environment for brazing professionals

Incorporated flux into the filler metal

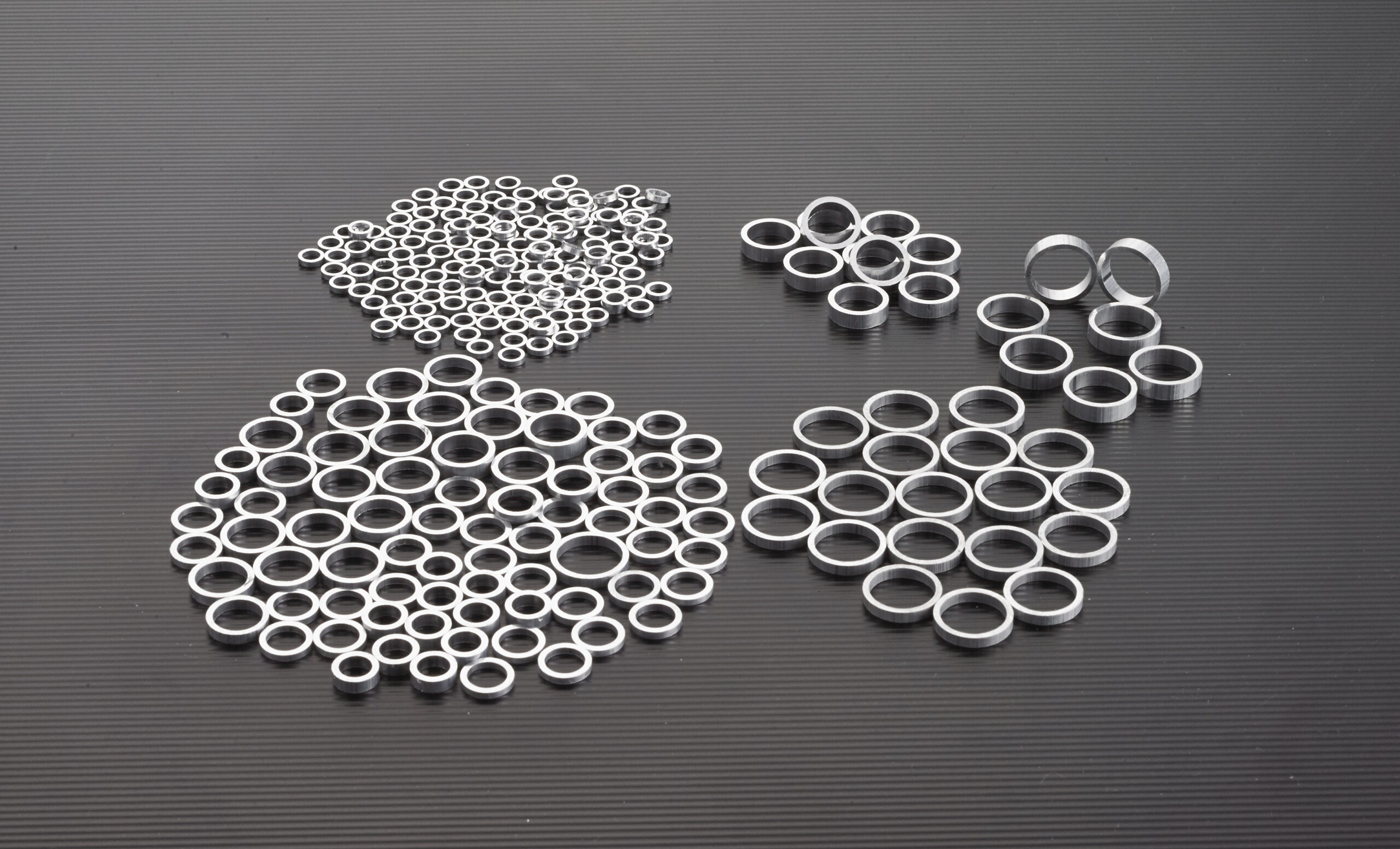

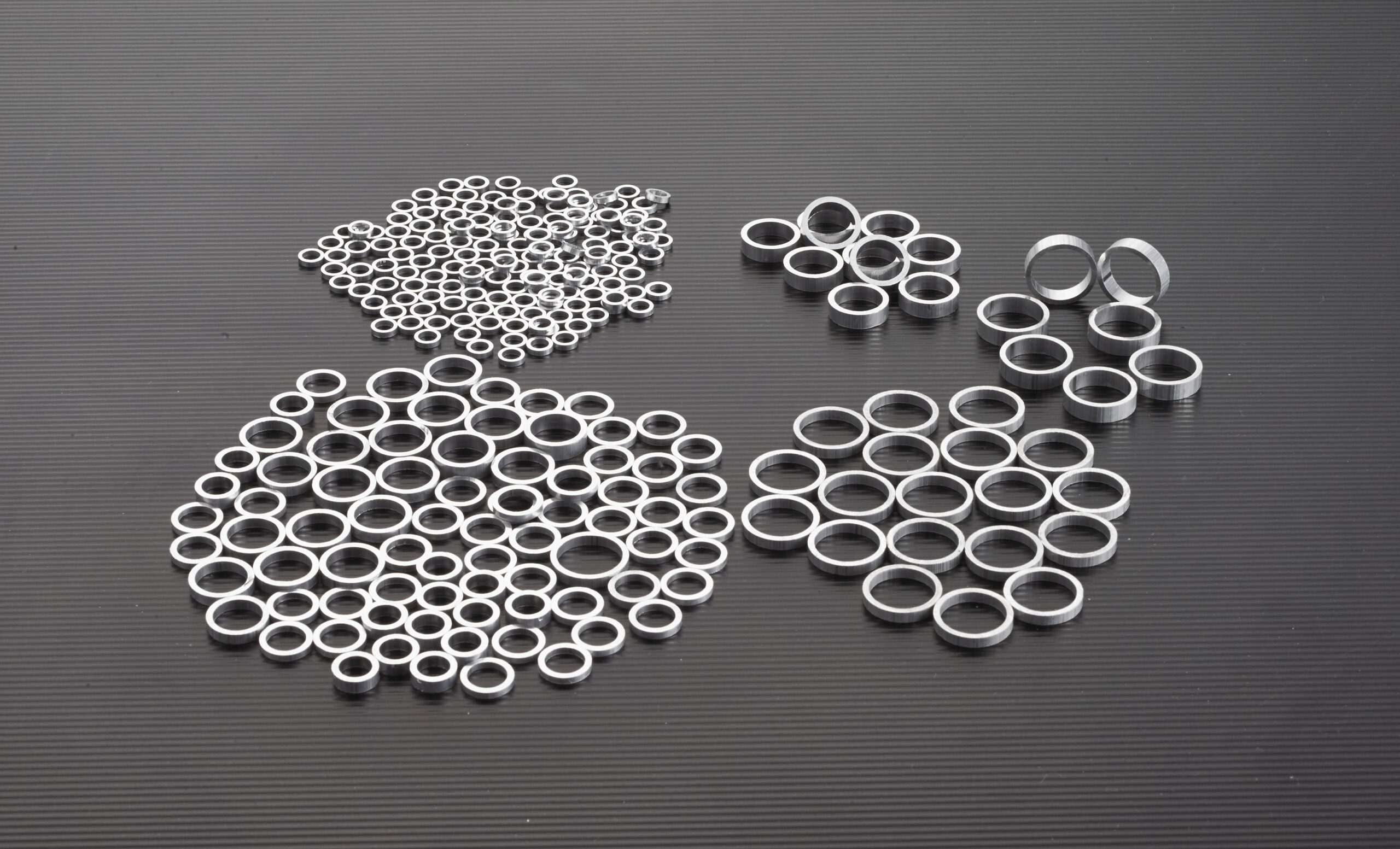

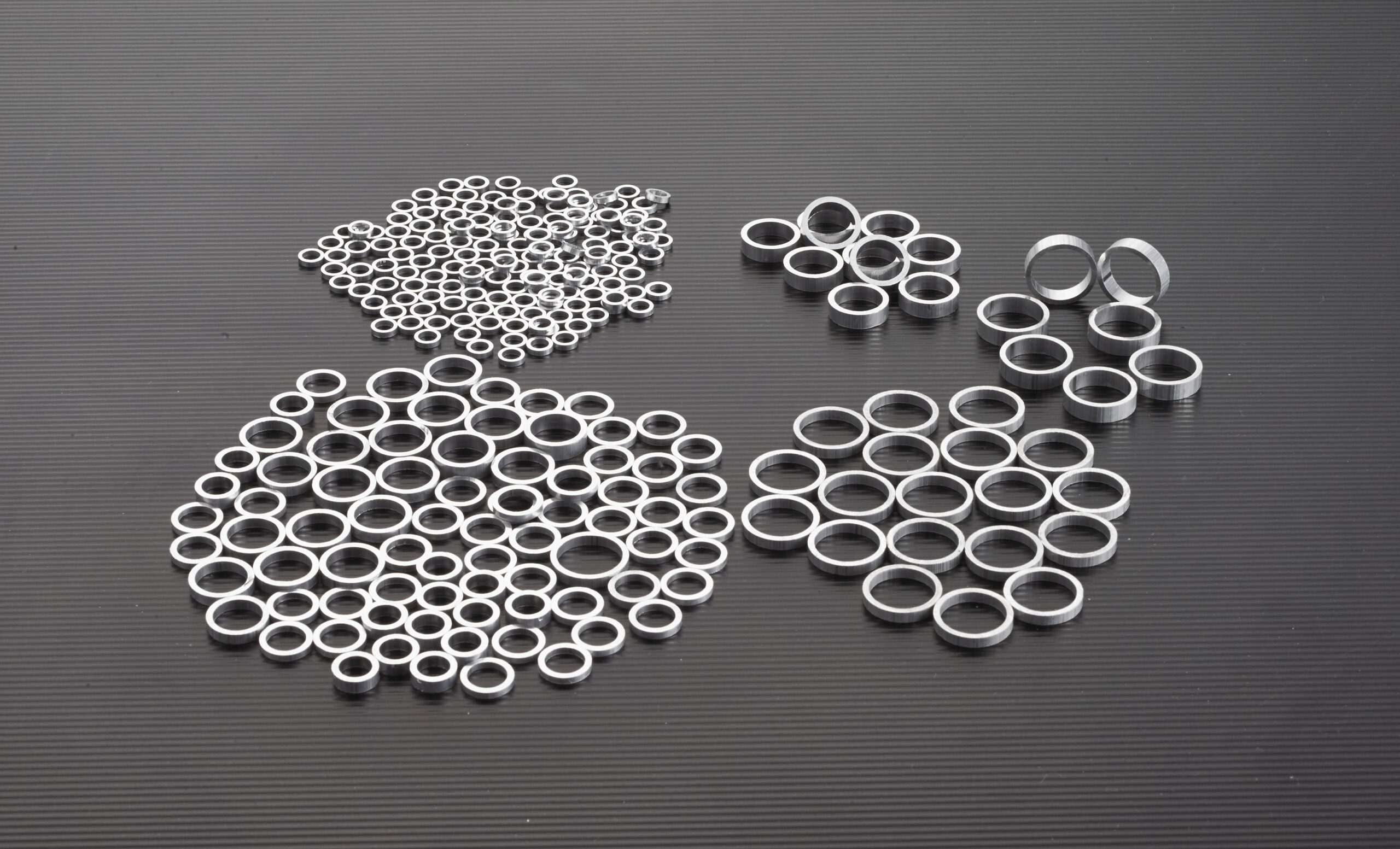

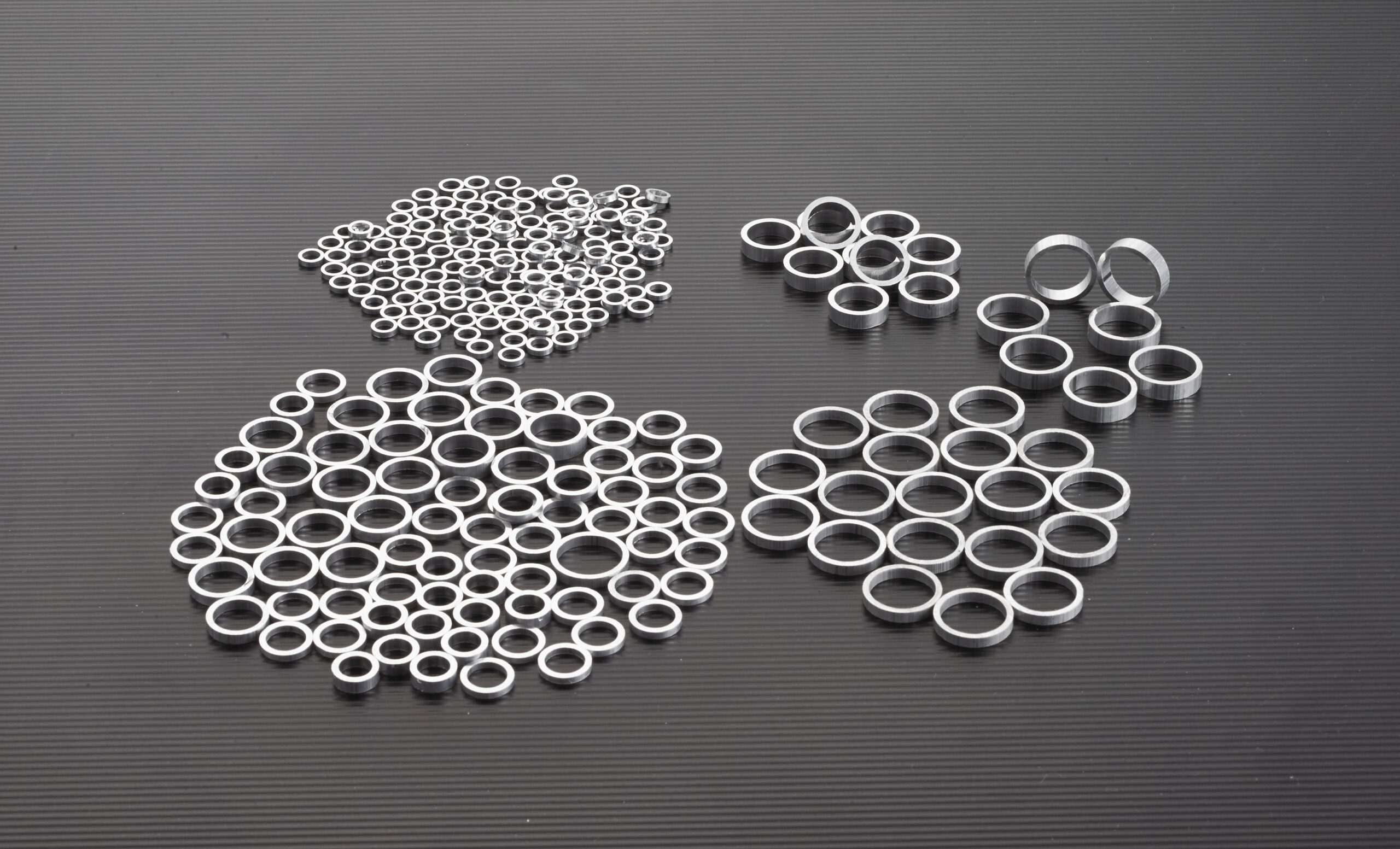

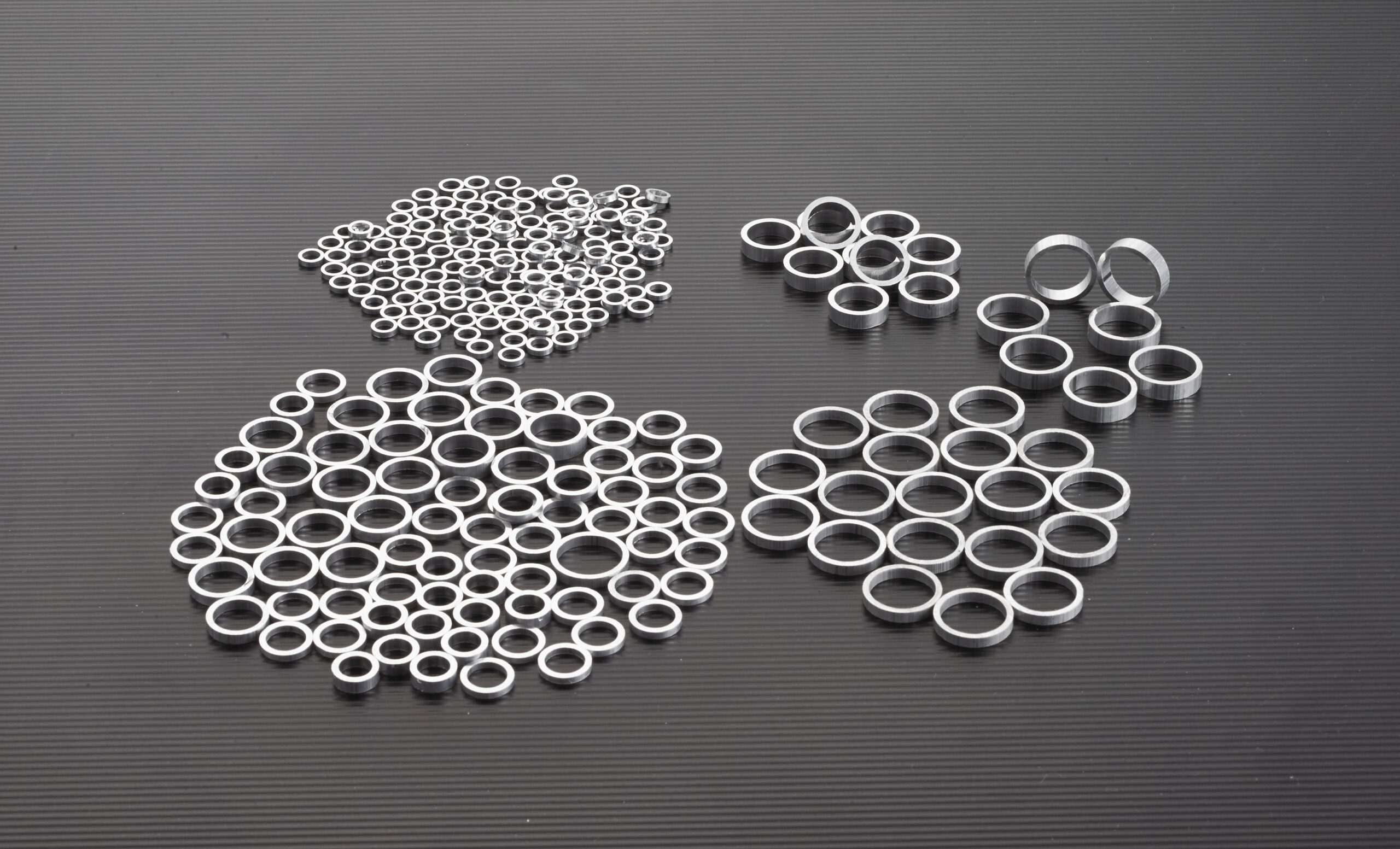

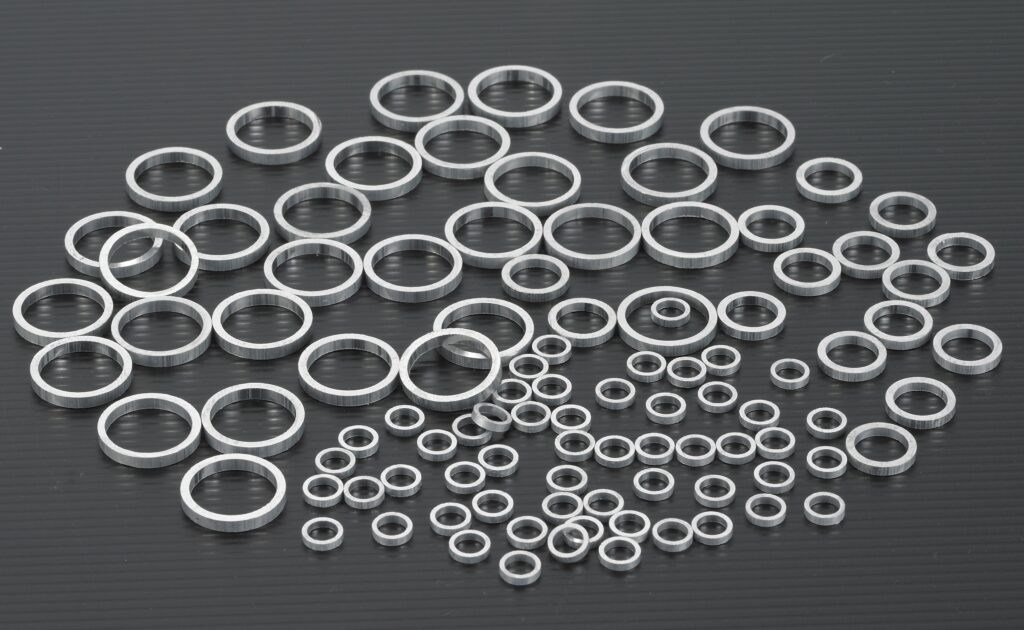

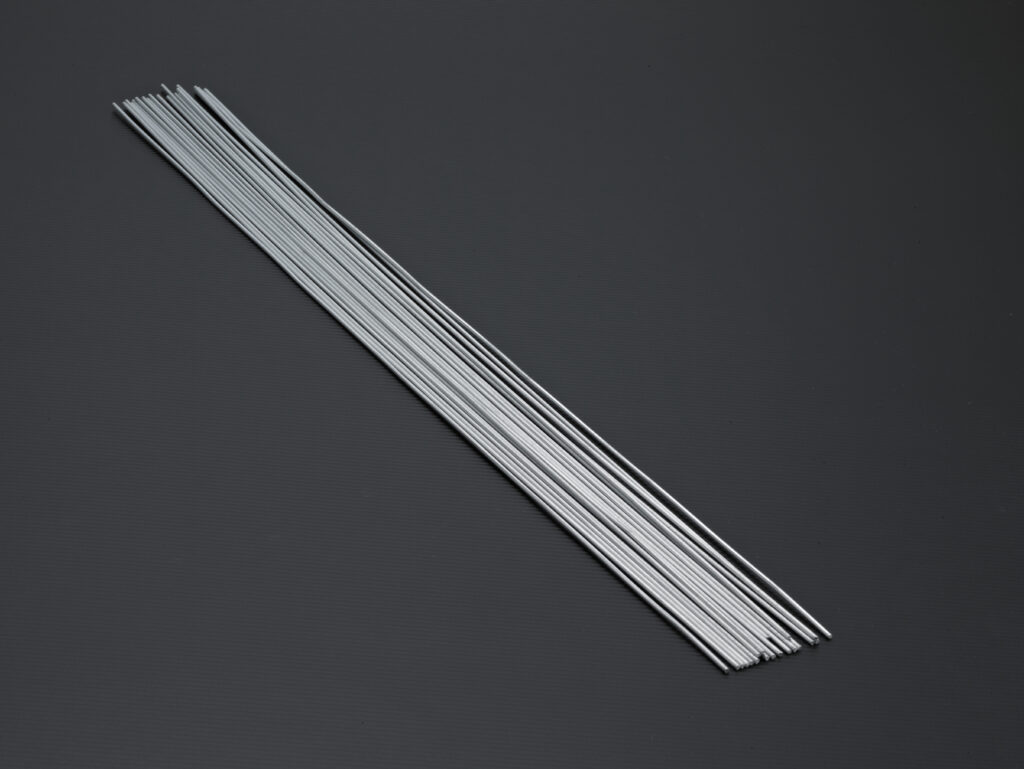

H-SERIES

Homogeneous Mixture-Type

SKA’s H-series brazing filler metals feature a homogeneous mixture of filler and fluxes, ensuring consistent composition and performance.

Solving Defects Caused by Flux Variation in Aluminum Brazing

A common challenge in aluminum filler metals is the wide variation in flux content, which can fluctuate by as much as ±5%. This often results in inconsistent brazing results. SKA’s groundbreaking H-series addresses this issue by significantly reducing the variation range to an exceptional ±0.1% or below, ensuring precise, stable, and superior brazing performance.

Exceptional and Consistent Brazing Quality

SKA’s H-series brazing filler metals are made with a carefully designed alloy composition, ensuring the filler metals and fluxes function effectively during the brazing process. By reducing ingredient variation, these brazing filler metals deliver consistently high-quality results.

With a trusted history of over 20 years in heat exchangers for HVACR and automotive industries, SKA’s H-series achieves brazing defect rates below 1%, guaranteeing precision, reliability, and excellent performance.

Efficient and Cost-Effective Automated Brazing Process

SKA’s H-series brazing filler metals enable seamless automation by providing consistent and exceptional brazing quality. These filler metals are specifically designed to match the base materials and brazing processes of customers, eliminating the need for complex equipment features. As a result, businesses can develop automated facilities more cost-effectively and simplify the management of the brazing process, leading to enhanced efficiency and reliability.

Clean Working Environment

In brazing processes, issues such as flux leakage through gaps and contamination from foreign substances can pose significant challenges. SKA’s H-series brazing filler metals are designed to prevent these issues by ensuring that flux does not leak or disperse, effectively eliminating risks of workplace contamination. This feature helps maintain a clean and efficient work environment.

Ensuring Worker Safety with SKA’s Brazing Filler Metals

Some brazing materials use binders to secure flux, but these substances can be harmful to workers’ health. SKA’s H-series brazing filler metals address this concern by containing only the necessary filler metals and fluxes for brazing, without any binders or additives. Consequently, the brazing process produces no fumes or dust, creating a safer and cleaner working environment for brazing professionals.

Remarkable Productivity and Cost Efficiency

SKA’s brazing materials are designed to deliver strong and consistent performance. This reliability helps reduce production costs and boost productivity. Compared to competitors’ products, SKA’s solutions are more efficient, making them the preferred choice for applications that demand high precision and dependability.

H-SERIES NOMENCLATURE

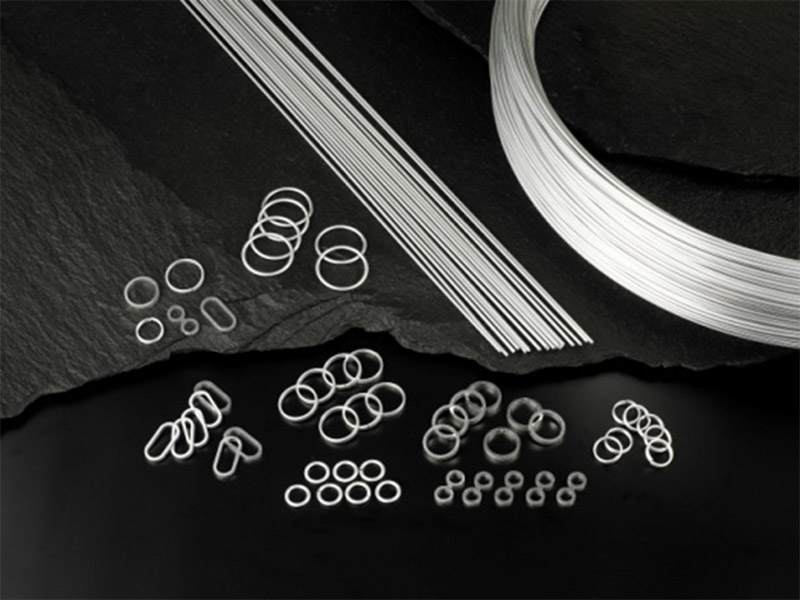

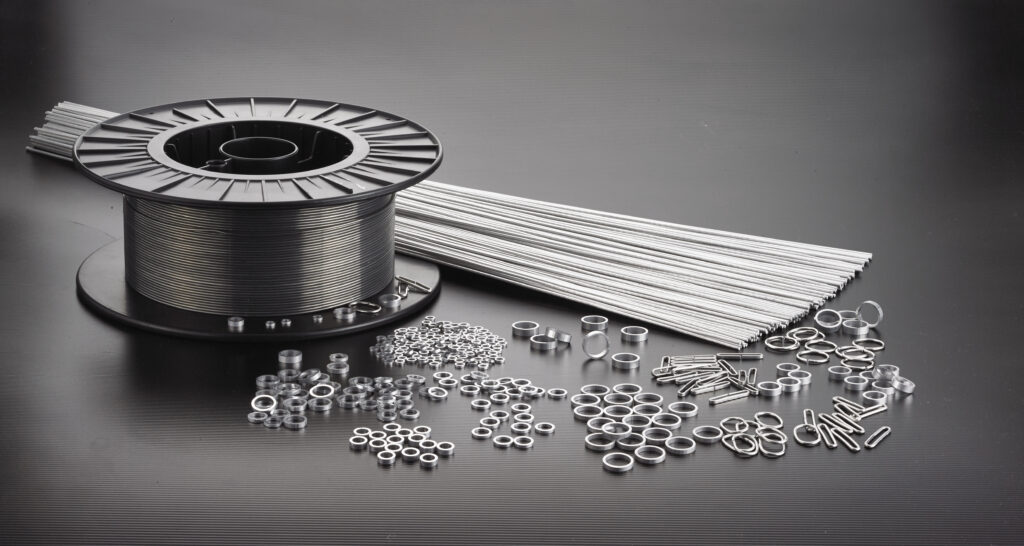

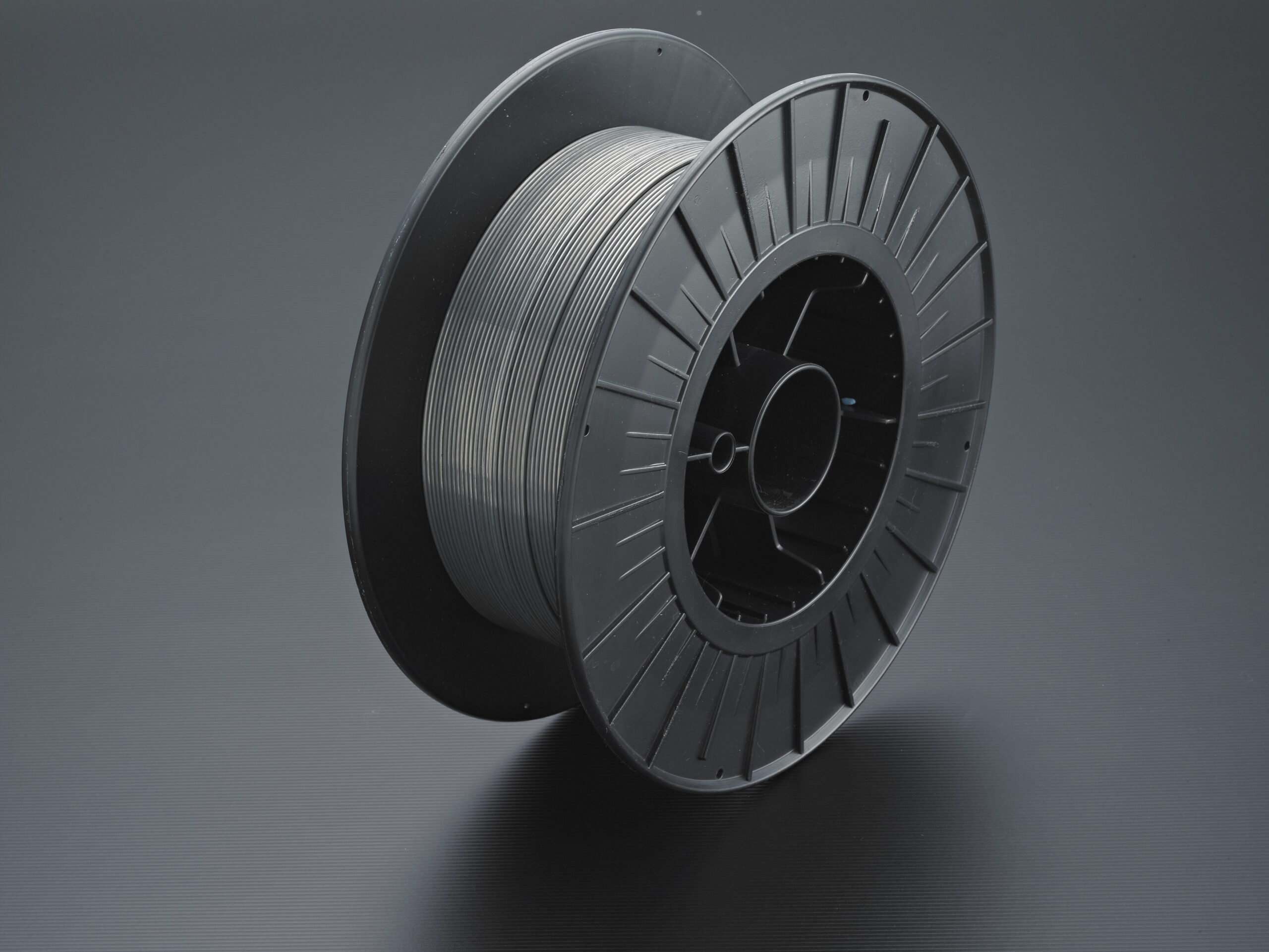

Flux-Cored Type Aluminum Brazing Filler Metal

What is a flux-cored type aluminum brazing filler metal? An aluminum brazing filler metal in which the flux is contained within its core.

What is a common issue with flux-cored aluminum brazing filler metals? Significant variation in flux content, which can fluctuate by ±5% or more. This variation can lead to inconsistent brazing results.

Discover the Advantage of SKA’s Flux-Cored Aluminum Brazing Filler Metals over Competitors’ Products

What is the advantage of SKA’s flux-cored aluminum brazing filler metals over competitors’ products? SKA maintains flux content variation within ±1% in its flux-cored aluminum brazing filler metals by using a forced injection process. This precise control ensures consistent brazing performance, giving SKA a competitive advantage.

C-SERIES NOMENCLATURE (FLUX-CORED TYPE)

SKA’s C-series brazing filler metals feature a flux-containing core, classifying them as flux-cored brazing filler metals. These are widely used across various industries.